Metallics are so in this year. I had been looking to buy or make a hip, industrial light fixture for my place for awhile when I came across this tiered brass number at Urban Outfitters. Read on to check out how to make one for yourself for about $15.

Supplies

10 ft. aluminum flashing, 6 in. tall

tin snips

tape measure

a crayon

single hole punch

wire

nail clippers

Directions

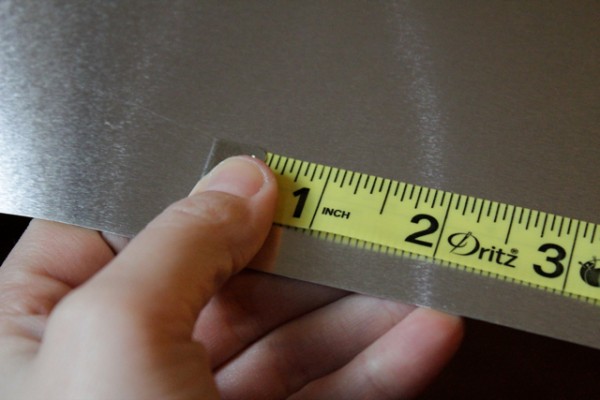

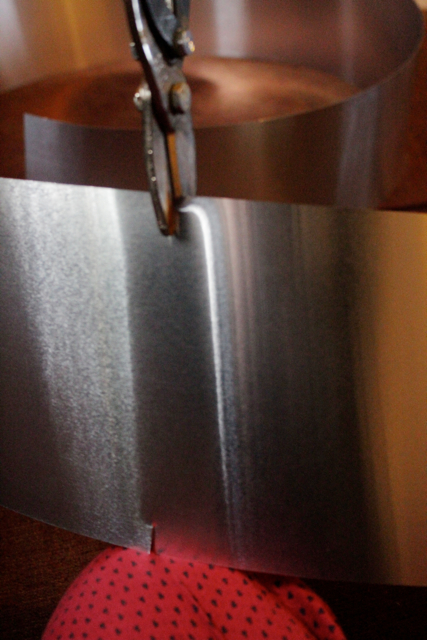

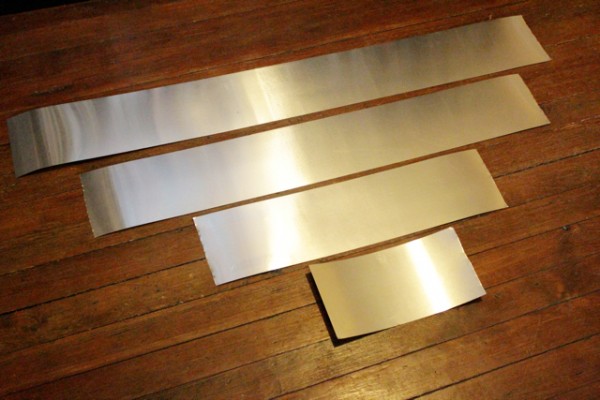

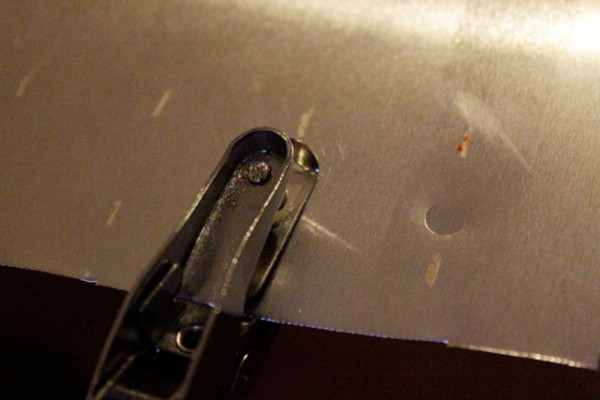

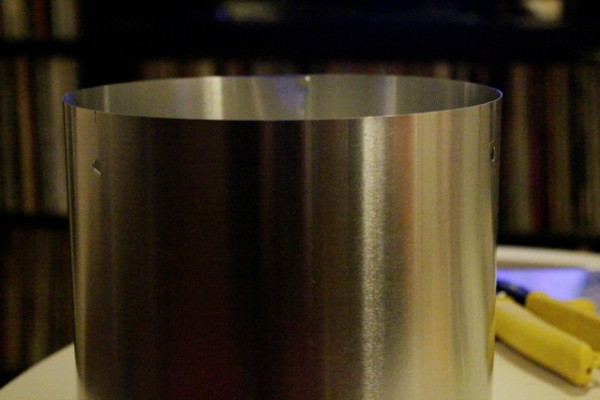

Cut your aluminum flashing into 4′, 3′, 2′ and 1′ lengths using the tin snips. I snipped a guide line at the top and bottom of my flashing as shown to help cut straight.

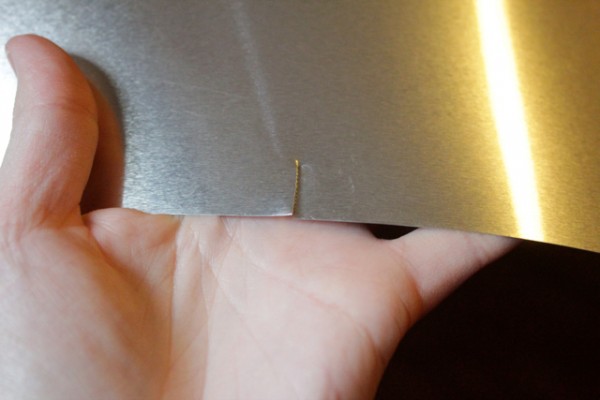

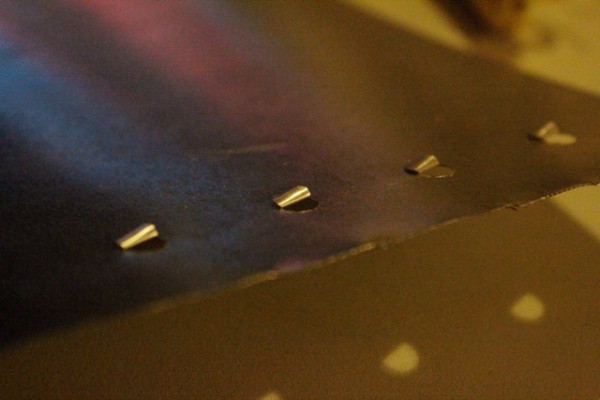

Set aside the 1 foot piece. Mark each end of each piece of aluminum. I made 5 marks, 1 inch apart with crayon. Punch holes at each marker using a paper punch (yep, a paper punch on metal!). I was only able to punch about half way through the metal. Then, I used a nail clipper to bend back the metal and flattened it the rest of the way with my thumb. Check it out:

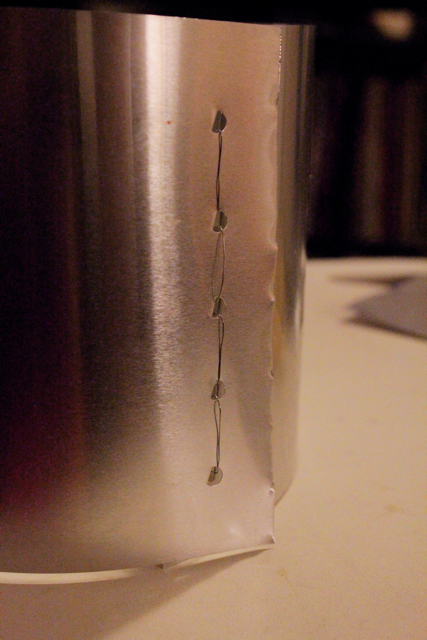

Next, cut four short lengths of wire. Thread the wire like twist ties through every two adjacent holes to create a loop with your aluminum flashing piece.

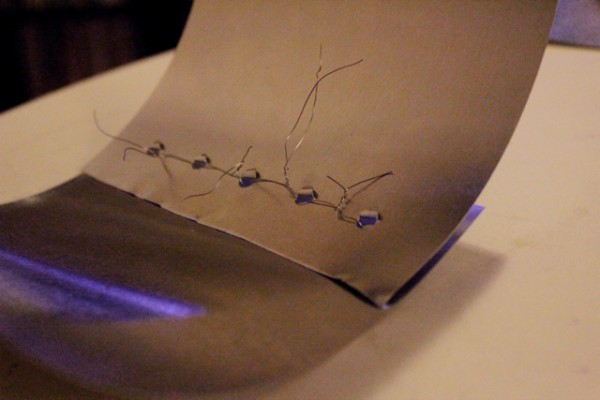

Punch three evenly-spaced holes along the top of each loop using the hole punch/nail clipper technique above.

Thread a long piece of wire through each of these new holes and hang them as shown. The hardest part is is getting them to hang level. I’m going to put three i-hooks in the ceiling around a built-in light fixture in my apartment to install this in my house. I can’t wait!

Hi Heidi,

A Crop-a-dile makes quick work of punching through tin, chip board and other thick items. you will get a nice clean hole and can save your nail clippers for your fingers. :)

Yeah- I made that before I learned about the cropadile! Thanks, lady :)

Aluminum flashing is an awesome material for a lot of different projects. As a long-term fan of the stuff, I have some additional advice to offer about it:

a. Like any other thin-gauge sheet metal, Aluminum flashing has EXTREMELY sharp and slightly-serrated edges when cut with anything but a wide-mouthed, industrial-grade, bench-or-floor-mounted shear. BE CAREFUL! Chain mail and a falconer’s gauntlet wouldn’t really be overkill here.

b. If you want to cut nice straight lines in your flashing, just use a steel ruler as a straight edge and score the aluminum with any ol’ razor knife – after a few firm passes with a dull razor, flashing snaps quickly and easily. A fresh razor blade will work as well, of course, but dull is better because the Aluminum will make it an old one in approximately 5 seconds.

c. A 1/16″ drill bit makes holes in Aluminum flashing like nobody’s business (and if you’re a crafter who’s not comfortable using a power drill, you might not want to be messing around with those aforementioned sharp edges anyhow.)

Thank you! That project was my first ever using aluminum flashing- your tips will be really helpful for my next one :)